If you need more proof that companies and consumers are concerned about the environment, consider the push for seaweed packing. Making plastic waste disappear is a great goal; of the billions of metric tons of plastic produced each year, National Geographic says 91% isn’t recycled. Finding an alternative to all this waste is desirable for a variety of reasons. Companies are now considering seaweed packaging to cut down on plastic pollution. But is seaweed packaging viable as a mechanism for the delivery of consumer products?

Shipping with Seaweed Packaging

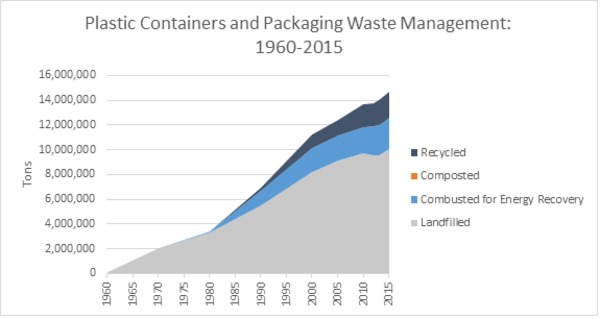

Having a biodegradable solution to plastic waste is a no brainer. Food is a particular culprit for plastic packaging; the Environmental Protection Agency (EPA) tracks the voluminous increase in plastic packaging for consumer goods and how little is actually recycled each year.

As companies consider alternatives to all the plastic, some standout examples of seaweed packaging are making their way into the marketplace. Forbes reports on:

- Whiskey manufacturers Glenlivet teamed up with a sustainable packaging company called Notpla to release their “Capsule Collection” of seaweed pod encased shots of their high-quality booze. The capsule is completely edible and biodegrades faster than fruit.

- Notpla also made the news this year when they did a single run of edible waters encased in seaweed packaging for the London marathon.

- Speaking of London, food delivery service Just Eat uses seaweed packaging around condiments. While the pods aren’t meant to be eaten (unless you want a full mouthful of catsup or mayo), they completely compost in kitchen food scrap bins and trashcans.

Forbes reports that Notpla is currently overwhelmed with inquiries and are in production to use this packing for everything from potato chips to packaging for dry consumer goods.

Notpla is already fielding competitor encroachment; Indonesian start-up Evoware made headlines on Greenbiz.com and is testing seaweed packaging made from farmed seaweed in their region.

According to Greenbiz, some of the seaweed packaging undergoing testing will cover everything from burgers to protein bars. Seaweed packaging is not only biodegradable and edible; it can be made to dissolve when water hits it, which is excellent for packaging tea or cereals.

Pros and Cons of Seaweed Packaging

The benefits of seaweed packaging, according to Greenbiz, extend beyond keeping plastic out of the ocean. They report it takes a hectare of ocean to create 40 tons of dry seaweed. During processing, that same volume can absorb 20.7 tons of CO2 emissions.

The only drawbacks at the moment seem to be the price; because seaweed packaging currently requires manual processing, it is more expensive than plastic. The second difficulty is figuring out how to scale production.

Seaweed has been in our kitchen for decades. But it seems that the plant also has applications beyond sushi or other recipes. While seaweed packaging has some kinks to work out, it seems clear that it holds the potential to help eliminate some of the plastic clogging our planet.

PKG Brand Design is always on the forefront of new CPG branding and packaging initiatives; please subscribe to our blog for the latest package design industry news!

-min-2.png)