Packaging size plays a key role in how products perform on retail shelves. It influences consumer perception, shelf visibility, and operational costs. Here’s what you need to know:

- Shelf Visibility: Larger packages act like billboards but reduce the number of units displayed (facings), while smaller packages fit more units and often get better placement.

- Consumer Perception: Bigger packages suggest value (bulk purchases), while smaller ones often feel premium or convenient for trial sizes.

- Retailer Preferences: Retailers favor packaging that maximizes sales per square foot and streamlines restocking.

- Logistics and Costs: Oversized packaging increases shipping and storage expenses due to dimensional weight pricing. Right-sized packaging reduces costs and improves efficiency.

Key takeaway: The right packaging size balances shelf presence, consumer appeal, and operational efficiency. Brands should test designs to ensure they stand out and meet retailer requirements while managing costs.

How Shelf Space and Packaging Dimensions Work Together

In retail, shelf space is a finite resource - every inch matters. Packaging dimensions play a big role in determining how products are displayed. The term facings refers to the number of identical product units visible at the front of the shelf. Here's the catch: the bigger the package, the fewer facings you can fit. Larger packages take up more horizontal and vertical space, limiting how many units can be displayed together. On the other hand, smaller packages allow retailers to stock more units or offer a broader range of SKUs in the same footprint. This delicate balance directly affects consumer choices, making packaging size a critical decision.

Retailers focus on maximizing sales per square foot, so your packaging needs to hit the sweet spot between being physically efficient and driving sales. Oversized packaging can crowd out other products, reducing variety - a move that may lead retailers to reject it or place it in a less visible spot. On the flip side, packaging that's too small might fail to grab attention as shoppers scan the shelves. Square or rectangular packaging is often more practical, as irregular shapes create wasted space, reducing facings and increasing restocking needs. Ultimately, how your product fits on the shelf plays a big role in how shoppers perceive its value.

"Retailers have limited shelf space and prioritize products that maximize sales per square foot." - Maadho

It's worth noting that 64% of shoppers try a new product simply because the packaging catches their eye. Additionally, 82% say they’re more likely to purchase after seeing or holding the product in-store. This means your packaging size and design can make or break whether your product even gets noticed.

How Larger Packages Affect Shelf Visibility

Larger packages have the advantage of acting like billboards. They offer extra room for bold graphics, brand messaging, and appealing product images - features that are especially useful in categories like bulk snacks or family-size cereals, where perceived value is key. However, the downside is fewer facings, which can make the product seem less available.

Height is another factor to consider. Products taller than the typical 12–18 inch eye-level range often end up on lower shelves, where there's more vertical clearance but far less visibility. Being on a bottom shelf can hurt impulse purchases, as shoppers naturally focus on items at eye level. Plus, larger packaging comes with added costs - higher shipping and storage expenses - and may require special secondary packaging to avoid damage during transit.

Advantages of Smaller Packages on Crowded Shelves

While large packages grab attention from a distance, smaller ones shine in tight, competitive spaces. Compact designs allow for more units per shelf, which can improve visibility in crowded retail environments. This efficiency often earns better shelf placement, as retailers prefer products that streamline labor and restocking, benefiting both the store and the shopper.

Smaller packages also cater to specific customer needs. Trial sizes, for instance, attract first-time buyers who want to sample a product without committing to a full-size purchase. Meanwhile, single-serve or portable formats appeal to on-the-go shoppers. These smaller packages often sit at eye level and are easy to grab, making them ideal for quick decisions. To make up for their reduced size, bold colors, high-contrast fonts, and strong branding are essential to stand out.

| Packaging Strategy | Impact on Facings | Retailer Benefit | Consumer Perception |

|---|---|---|---|

| Oversized Packaging | Low (Fewer units) | High visibility for the category | High value/Bulk |

| Right-Sized | High (More units) | Maximizes sales per sq. ft. | Convenience/Portability |

| Shelf-Ready (SRP) | Consistent | Reduced labor/restocking | Organized/Reliable |

| Unique/Custom Shapes | Variable | Brand differentiation | Luxury/Innovation |

sbb-itb-0c3a5ed

How Packaging Size Shapes Consumer Perception

Packaging size does more than just determine how much shelf space a product takes up - it plays a key role in shaping how consumers view your product before they even glance at the label. The size of the packaging can signal everything from quality to value and even hint at the intended audience, making sizing decisions a strategic part of product marketing.

Perceived Value and Bulk Packaging

The size of a package can strongly influence how customers perceive its value. Larger packages often suggest a better deal, as they imply a lower cost per unit, appealing to bulk buyers. However, studies reveal that smaller packages are often seen as higher quality compared to larger ones from the same brand. This perception stems from the association of smaller sizes with higher unit prices, which consumers often interpret as a sign of premium quality.

"A product in a smaller package is rated more favorably than the equivalent product in a larger package." - Dengfeng Yan, University of Texas at San Antonio

Interestingly, this "small equals premium" effect is most pronounced when a product is viewed in isolation. On the other hand, when shoppers focus on the overall price rather than the price per unit, larger packaging tends to win out as the better value. The key takeaway? Bulk packaging is great for communicating value, but smaller packages can justify higher price points and create a premium impression. This dynamic directly impacts shelf performance, where size influences perceptions of quality and value.

Convenience and Appeal of Trial Sizes

Trial sizes are another critical aspect of packaging strategy, offering a convenient entry point for first-time buyers and busy, on-the-go shoppers. These smaller packages reduce the commitment level, making them perfect for impulse buys at checkout counters or quick grabs in convenience stores. In fact, 72% of American consumers report that packaging design impacts their purchasing decisions. With limited space on smaller packages, it’s crucial to create a visually engaging and clear design that grabs attention and communicates the product’s value effectively.

Balancing Packaging Size with Logistics and Cost

Packaging size plays a crucial role in both product presentation and operational expenses. The dimensions of your packaging directly influence shipping, storage, and restocking costs. Making informed decisions about packaging size is key to striking the right balance between visual appeal on shelves and cost efficiency.

Cost Impact of Larger Packaging

Bigger packaging often leads to higher costs, which can eat into profit margins. Shipping carriers like UPS, FedEx, and USPS use dimensional weight (DIM weight) pricing. This means they charge based on the size of the package rather than just its actual weight. For example, a lightweight item in an oversized box may cost significantly more to ship than a heavier product in a compact package.

"Carriers like UPS, FedEx, and USPS use dimensional weight (DIM weight) pricing, meaning larger boxes cost more to ship even if they're lightweight." - Collin Box & Supply

In addition to higher DIM weight charges, large packaging requires more storage space and often needs extra void-fill materials to protect the product during transit. These added expenses increase the cost per unit and can result in more frequent restocking, further driving up logistics costs. Adjusting packaging dimensions can help mitigate these challenges and reduce unnecessary expenditures.

Right-Sized Packaging for Better Operations

To address these cost concerns, many companies are turning to right-sized packaging, which improves operational efficiency. Known as "skinny design", this approach focuses on reducing the cubic volume of packaging. By doing so, businesses can fit more units into shipping containers, trucks, and retail shelves. McKinsey & Company reports that adopting skinny design strategies can lead to more than 10% growth in bottom-line savings.

"The largest savings come from reducing transportation cost per unit by fitting more product in containers and trucks." - Dave Fedewa, Daniel Swan, Warren Teichner, and Bill Wiseman, McKinsey & Company

Right-sized packaging also offers other benefits, such as minimizing product damage during transit. Reduced movement inside the box lowers the chances of returns and replacement costs. Additionally, it enhances shelf efficiency by allowing more units to be stocked, which can reduce stockouts and boost sales. In fact, McKinsey found that improving shelf density can drive 4% to 5% growth in top-line revenue. With stockout rates reaching 30% in late 2021 (double the pre-pandemic levels), optimizing shelf space has become a critical advantage.

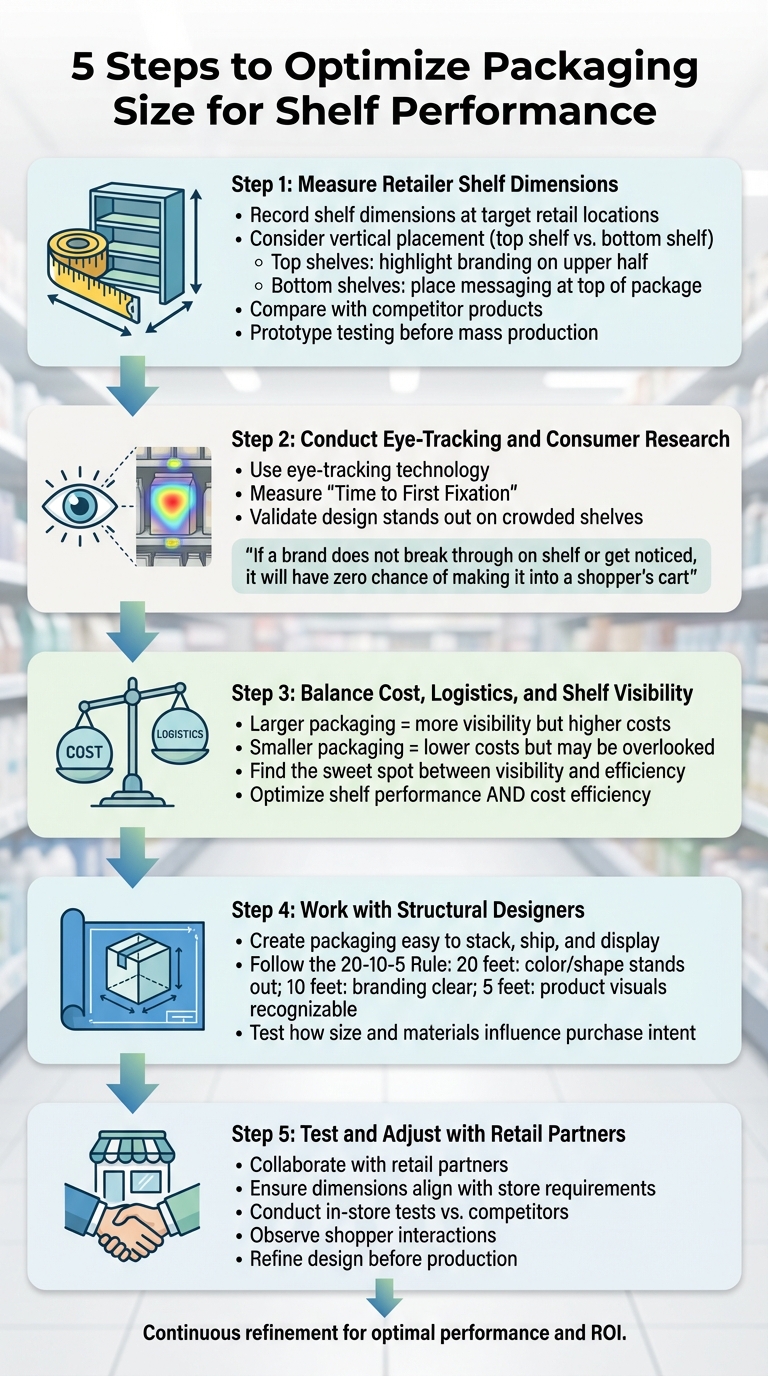

5 Steps to Optimize Packaging Size for Shelf Performance

5 Steps to Optimize Packaging Size for Retail Shelf Performance

Designing packaging that works well on retail shelves requires a clear understanding of shelf constraints. These five steps will help you create packaging that not only grabs attention but also functions efficiently in a retail setting.

Step 1: Measure Retailer Shelf Dimensions

Start by recording the dimensions of shelves at your target retail locations. Shelf sizes can vary depending on where your product will be placed - whether it’s in a refrigerator, on a standard shelf, at checkout, or on an end cap. Vertical placement also matters: products on top shelves (viewed from below) should highlight key branding on the upper half, while bottom-shelf items (viewed from above) need messaging at the top of the package to catch the eye. Compare these dimensions with competitor products to ensure your packaging fits without causing stocking challenges. Prototype testing is essential to confirm your design works as intended before moving to mass production.

Step 2: Conduct Eye-Tracking and Consumer Research

Use consumer testing and eye-tracking technology to see how well your packaging attracts attention. Metrics like "Time to First Fixation" reveal how quickly shoppers notice your product. Eye-tracking results can validate whether your design stands out on a shelf crowded with competitors. As Jason Bradbury, Vice President of Client Development at Behaviorally, explains:

"If a brand or product does not break through on shelf or get noticed, it will have zero chance of making it into a shopper's cart for purchase."

This research ensures your packaging not only gets noticed but also communicates its message clearly in a competitive retail environment.

Step 3: Balance Cost, Logistics, and Shelf Visibility

Finding the right packaging size means balancing visibility with practical considerations like shipping and storage costs. Larger packaging often stands out more but can increase operational expenses. On the flip side, packaging that’s too small might get overlooked in a crowded display. Striking this balance is key to optimizing both shelf performance and cost efficiency.

Kevin Keating, President of PKG Brand Design, points to another trend:

"Many brands are using the front and backsides as dual principle display panels (PDF) providing flexibility to merchandise the package either horizontally or vertically, depending on the retailers’ preference”.

Step 4: Work with Structural Designers

Collaborate with structural design experts to create packaging that’s easy to stack, ship, and display. Follow the 20-10-5 Rule: your package should stand out at 20 feet, keep branding clear at 10 feet, and make product visuals recognizable at 5 feet. Mike Moussallem from Explorer Research highlights the importance of this rule:

"At 20 feet away, make sure your package color or shape clearly stands out on shelf."

Beyond logistics, structural design can enhance consumer appeal by making the product easier to interact with. Testing how size and materials influence purchase intent is especially important for in-store shopping, where physical interaction plays a big role.

Step 5: Test and Adjust with Retail Partners

Collaborate with your retail partners to ensure your packaging dimensions align with store requirements and maximize shelf facings. Conduct in-store tests to observe how your product performs against competitors and how shoppers interact with it. This phase helps identify and resolve any issues with merchandising or restocking, reducing risks for retailers and refining your design before production.

Conclusion

When it comes to packaging design, success lies in finding the sweet spot between visual appeal and practical functionality. The dimensions of your packaging play a critical role in meeting consumer expectations, satisfying retailer requirements, and keeping costs in check. With the right size, your product can grab attention on the shelf, communicate its value effectively, and fit seamlessly into a retailer's merchandising system. On the flip side, poorly chosen dimensions can lead to missed opportunities, like unfavorable shelf placement or higher logistical expenses.

Creating effective packaging means balancing three key factors: consumer perception, retailer requirements, and operational considerations. Packaging size influences how customers perceive value and volume. Retailers, meanwhile, look for packaging that fits their shelf layouts, improves stocking efficiency, and maximizes sales per square foot. Operationally, the right packaging can help reduce shipping costs, optimize material use, and streamline inventory management.

The best brands don't leave this to chance - they test their packaging in real-world scenarios before committing to production. For instance, SmashBrand’s redesign of Kool-Aid's pouch addressed consumer frustrations and led to a 48-point boost in purchase preference. Similarly, WildPaw saw a 45-point jump in purchase intent after refining its packaging to better highlight ingredients and functionality.

PKG Brand Design's Consumer First® approach embodies this strategic mindset. By weaving together consumer insights, brand strategy, and structural design, they create packaging that not only performs on the shelf but also drives sales. Their services cover everything from eye-tracking studies to final production artwork, ensuring your packaging meets the needs of shoppers, retailers, and operational teams alike.

Whether you're gearing up to launch a new product or revamping an old favorite, expert design guidance can make all the difference. Sometimes, the success of your packaging boils down to a matter of inches - and the thoughtful strategy behind them.

FAQs

How does the size of packaging influence consumer perception and buying decisions?

Packaging size plays a major role in shaping how people view a product and whether they decide to buy it. Smaller packaging often gives off a sense of being premium or higher quality, while larger options tend to suggest better value for money. That said, these impressions can differ based on the type of product and what consumers expect from it.

The design of the packaging - both its shape and size - also influences how much product people believe they're getting. For instance, tall, narrow containers might seem like they hold less than they actually do, whereas wider designs can give the impression of abundance. By carefully selecting packaging dimensions, brands have the power to shape perceptions of quality, value, and quantity, which can directly impact buying behavior.

How does oversized packaging impact costs and logistics?

Oversized packaging can create challenges that hit both your budget and logistics hard. When packages are larger than necessary, shipping costs often spike due to dimensional weight pricing - a model that factors in the size of a package along with its actual weight. For businesses handling e-commerce or bulk shipments, these costs can pile up fast.

In retail settings, oversized packaging is a space hog. It eats up valuable shelf space, reducing the number of products that can be displayed. This not only disrupts store organization but can also hurt product visibility, potentially leading to lower sales. By resizing and optimizing packaging, businesses can cut costs while improving the efficiency of shelf displays, benefiting both retailers and customers.

How does packaging size influence shelf visibility, and how can brands optimize it?

Packaging size is a big deal when it comes to grabbing attention on retail shelves and making the most of available space. Striking the right balance between visibility and practicality helps products stand out to shoppers while ensuring shelves stay organized and efficient. Well-sized packaging catches the eye, making products more noticeable and appealing.

To get the most out of packaging, brands should aim for designs that are bold enough to draw attention without being overpowering. This approach allows for better shelf layouts and a wider variety of products. Smartly sized packaging can even boost impulse buys by maximizing the use of limited space. Careful decisions about package dimensions not only enhance product visibility but also create a smoother shopping experience, which can lead to higher engagement and sales.